Introduction to Nutraceutical Manufacturing Challenges

Nutraceutical manufacturing requires strict process controls to produce safe, effective products. Central challenges include precise powder blending, maintaining batch uniformity, and safeguarding active ingredients from unwanted reactions or degradation. Even minor inconsistencies can impact not just efficacy, but also safety and compliance, which is why reliable equipment like the ribbon mixer is fundamental in modern nutraceutical plants.

As consumer demand for supplements and functional foods grows, so does the need for advanced mixing technology that can handle delicate bioactive compounds, vitamins, minerals, and botanicals without compromising quality. Beyond batch-to-batch consistency, manufacturers strive for production methods that minimize downtime, reduce costs, and streamline regulatory adherence.

Understanding Ribbon Mixers

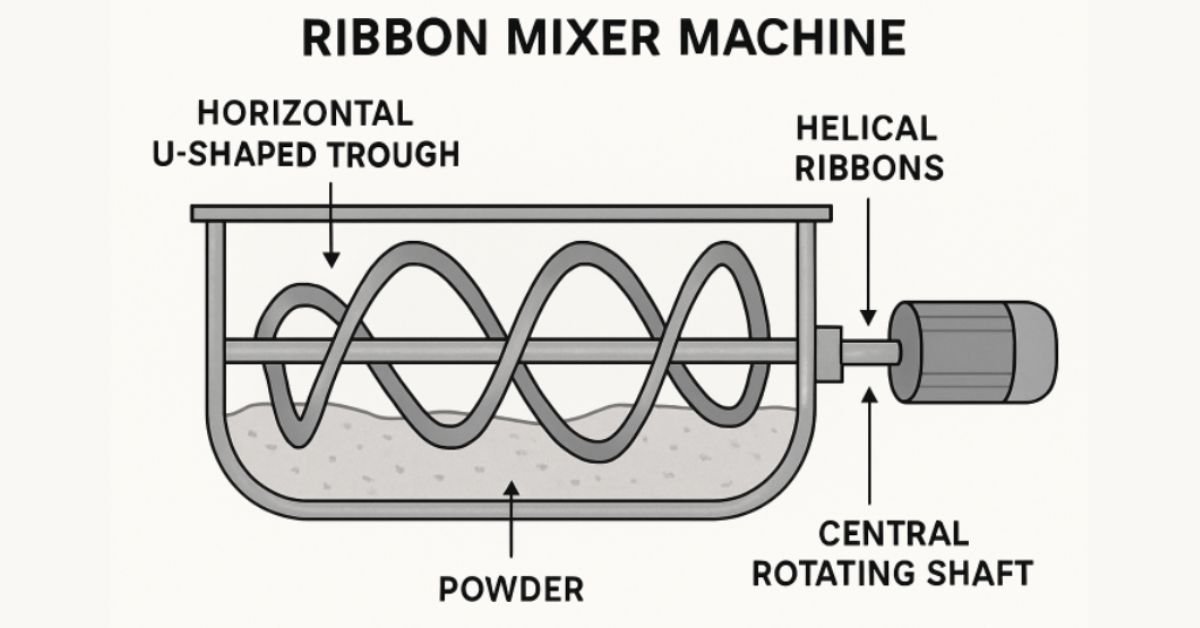

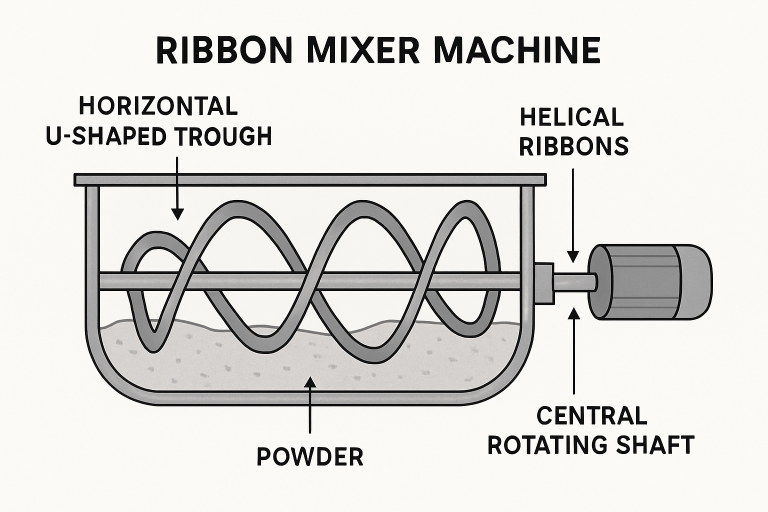

A ribbon mixer is an industrial blending machine designed with a horizontal U-shaped trough and a helical ribbon agitator. As the central shaft turns, the ribbons move material both along the horizontal axis and towards the ends of the trough. This simultaneous axial and radial agitation ensures rapid and thorough mixing of powders, granules, and minor liquid additions, producing a highly homogenous product in each batch.

The simple yet effective design of ribbon mixers reduces dead zones, eliminates pockets of unmixed material, and accommodates a wide range of product viscosities. For nutraceutical manufacturers blending ingredients of varying particle size and density, this is a significant advantage, enabling adherence to strict quality standards and uniformity mandates.

Key Advantages of Ribbon Mixers in Nutraceutical Production

- Uniform Mixing: Ribbon mixers excel at evenly distributing active and inactive ingredients, ensuring every capsule or sachet contains the correct formulation. Uniformity is essential for both clinical efficacy and regulatory approval, especially in products where precise dosages are critical.

- Scalability: Ribbon mixers are available in a wide range of capacities, making it easy for producers to scale from pilot batches to full-scale manufacturing without equipment changeovers. This flexibility minimizes capital expenditures and streamlines process validation for growing operations.

- Energy Efficiency: Compared to more aggressive or high-speed mixing technologies, ribbon mixers offer energy cost savings without sacrificing blend quality. Lower energy requirements also align with sustainability initiatives and help reduce a facility’s carbon footprint.

- Gentle Handling: Many nutraceutical ingredients—such as probiotics, enzymes, and vitamins—are sensitive to heat and shear. The low-intensity mixing action of ribbon mixers protects these fragile compounds, preserving potency and bioactivity throughout processing.

Comparative Analysis: Ribbon Mixers vs. Alternative Mixing Technologies

When evaluating mixing technologies, it’s helpful to consider production goals, material characteristics, and regulatory considerations. Ribbon mixers serve as generalists but face healthy competition from specialized machines:

- Rotary Batch Mixers: These machines achieve rapid blending by tumbling ingredients within a sealed drum, reducing blending times by up to 90% in some applications. As reported in Processing Magazine, switching to rotary batch mixers enabled some nutraceutical producers to accelerate output and streamline changeovers dramatically.

- Plow Mixers: Utilizing high-speed blades attached to a central shaft, plow mixers agitate and suspend ingredients for rapid blending—sometimes achieving up to 2000% faster mixing times than ribbon mixers.

However, the simplicity, versatility, and gentle action of ribbon mixers continue to make them a staple in facilities where batch integrity and low-shear handling are top priorities. Regulatory guidance supporting validated blend uniformity in nutraceutical products has made the ribbon mixer the backbone of many quality-driven production lines.

Best Practices for Implementing Ribbon Mixers

1. Regular Maintenance

Consistent upkeep is key to preventing contamination and mechanical breakdowns. Cleaning schedules should align with product changeovers, while bearings, seals, and drive systems require periodic inspection to guarantee uninterrupted performance and reproducible batches.

2. Operator Training

Hands-on, comprehensive training equips operators to adjust load sizes, speed, and ingredient addition sequences. Well-trained staff are better able to optimize runs, troubleshoot problems, and maximize equipment lifespan, which positively impacts overall productivity.

3. Process Optimization

Every product may require slight adjustments to blending time, ribbon speed, or fill rate. Routine process verification—such as in-process testing and post-blend analysis—ensures that blends meet specifications while highlighting opportunities to improve yield and consistency further.

Conclusion

Ribbon mixers offer a reliable, efficient, and gentle solution for nutraceutical manufacturers determined to uphold high standards of quality and consistency. By adopting robust maintenance practices, investing in operator expertise, and consistently reviewing processes, production teams can leverage ribbon mixers not only as blending workhorses but also as strategic assets driving ongoing improvement in nutraceutical production.

Ethan Cole is a passionate blogger at Aldalive.com, sharing fresh ideas and engaging content on lifestyle, technology, and everyday trends. With a love for writing and exploring new topics, Ethan aims to make information simple, useful, and inspiring for readers worldwide.