Maintaining the integrity of pipeline systems is essential for safeguarding both the environment and critical infrastructure. Rapid detection of leaks not only helps prevent costly damages and repairs but also minimizes risks to public health and ecosystems. To address the ever-present challenge of pipeline leaks, engineers and operators now rely on advanced detection techniques that combine efficiency, accuracy, and safety. Among these modern solutions, instruments such as the smoke pump tester play a pivotal role in leak detection, streamlining the process for field technicians.

Technological advancements have enabled pipeline operators to adopt methods tailored for various scenarios—from simple visual inspections to cutting-edge, real-time monitoring systems. As infrastructure ages and regulatory pressures increase, utilities and companies are turning to innovative strategies to stay ahead of leaks and maintain operational excellence.

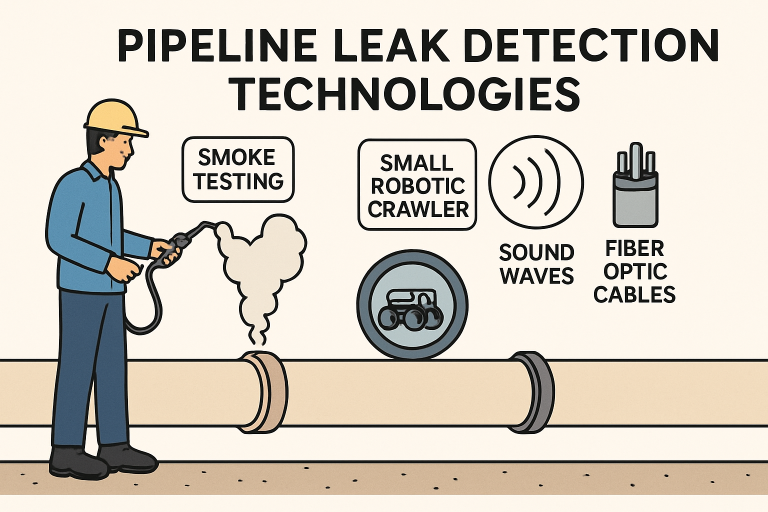

Smoke Testing

Smoke testing is one of the most straightforward yet powerful techniques for detecting leaks in pipelines, especially sewer systems. This process involves introducing a visible, non-toxic smoke into the pipeline. If there are cracks or leaks, the smoke will emerge at the surface, quickly revealing the location of the defects. The use of smoke-testing equipment, such as a smoke pump tester, allows technicians to easily pinpoint issues without digging or disrupting the surroundings extensively, resulting in significant time and cost savings.

According to the U.S. Environmental Protection Agency, smoke testing is an efficient way to identify illicit connections and inflow sources, which are common contributors to system inefficiencies and environmental hazards. The process is safe for workers, residents, and pets and offers a non-destructive alternative to more invasive inspection methods. This low-cost technique remains a mainstay for municipalities and utility providers due to its simplicity and effectiveness.

Robotic Inspections

Robotic non-destructive testing (NDT) has made deep inroads into pipeline management, providing operators with sharp visual and analytical insights into pipeline conditions. These robots—equipped with cameras, ultrasonic sensors, and sometimes even advanced sampling tools—can traverse long sections of pipelines that are otherwise unsafe or inaccessible to humans. Operating remotely, they capture high-resolution imagery and structural data in real time, enabling inspectors to make informed, immediate decisions about pipeline integrity.

Beyond visual inspection, NDT robots can also be fitted with sensors that detect surface cracks, corrosion, or blockages. Their ability to send data wirelessly means inspections are faster and cause less operational downtime.

AI and Machine Learning

Artificial intelligence and machine learning technologies mark the forefront of predictive maintenance and fault detection in pipeline systems. These systems are designed to process massive volumes of sensor, flow, and operational data, learning to recognize standard patterns and quickly identifying anomalies that may signal a leak or imminent failure. AI’s role is not just limited to data analysis; it also helps prioritize maintenance tasks, predict failure points before they occur, and reduce false alarms.

By integrating AI with sensors deployed along pipeline corridors, operators gain 24/7, autonomous monitoring capabilities that dramatically cut down response times and repair costs.

Acoustic Monitoring

Acoustic monitoring works by deploying sensors that listen for the unmistakable sound signatures of leaks. Pressurized fluids escaping from a pipe generate specific acoustic signals that can be identified by sophisticated algorithms analyzing the frequency and amplitude of the sound waves. One of the key advantages of this technique is its continuous operation, which provides real-time alerts and enables operators to respond to even small leaks early.

Acoustic technology has proven invaluable in both urban water supplies and large-scale oil and gas transmission lines, where detecting minor leaks before they escalate into severe incidents is essential.

Fiber Optic Sensing

Fiber optic sensing represents another leap forward for pipeline monitoring. These systems use fiber-optic cables laid along a pipeline’s length to continuously detect changes in temperature, pressure, strain and vibration, key indicators of leakage or external disturbances. If a leak occurs, the immediate change in local conditions triggers an alert that pinpoints the exact location within meters. According to Pipeline Journal, these technologies are helping operators overcome challenges and increase the overall value of fiber-optic monitoring.

Fiber-optic systems operate in real time and can span extensive pipeline lengths, making them particularly useful for remote or difficult-to-monitor regions. The technology supports both preventative maintenance and rapid incident response, combining high accuracy with minimal environmental impact. Its robust, continuous data stream is invaluable for asset protection and regulatory compliance.

Conclusion

The dynamic landscape of pipeline leak detection is continuously evolving, powered by advances in engineering, data science, and sensing technology. From time-tested smoke testing and adaptable robotic inspections to the predictive potential of AI, sensitive acoustic monitoring, and cutting-edge fiber optics, modern methods are equipping pipeline operators with the tools needed for a safer, more efficient future. Investing in these innovative solutions not only protects valuable assets but also ensures that environmental and community well-being remain at the forefront of pipeline management.

CLICK HERE FOR MORE BLOG POSTS

John Authers is a seasoned and respected writer whose work reflects the tone, clarity, and emotional intelligence that readers value in 2025. His writing blends deep insight with a natural, human voice—making complex ideas feel relatable and engaging. Every piece he crafts feels thoughtful, original, and genuinely worth reading.